Numerical Modeling of Electro-Hydrodynamic Flow Within an Electrostatic Precipitator

Electrostatic precipitators (ESPs) have been used in industry for over a century, as a filtration device to remove particulate matter (PM) from air. In relation to coal-fired power plants, they were installed as a means to remove the flue gases and fly ash that resulted from the plants’ combustion processes, one of which is mercury emissions. Powder activated carbon is used in conjunction with ESPs to remove mercury emissions from the flue streams via adsorption.

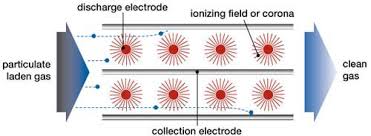

The most common ESP design, simplified, consists of a large chamber with an inlet nozzle at one end, and an outlet nozzle at the other. Inside, discharge electrodes are centered and aligned between large collection plates. The electrodes are negatively charged, while the plates maintain a positive charge. As a result, the negatively charged PM is directed to the collection plates as it passes through the system. The plates are discharged periodically, and PM is collected in hoppers at the bottom of the ESP.

Powder activated carbon (PAC) is introduced into the flue gas stream as it enters the ESP to capture mercury, and is then collected by the ESP along with other fly ash. However, it is believed that particle size and collection speed may hinder the efficiency of this process, leading to the environmental cost of PAC outweighing the benefit of its use. Professor Clack and his group are modelling the hydrodynamic flow of particles within an ESP, using COMSOL© Multiphysics Software, to determine the efficiency of mercury collection by PAC and PAC collection by the ESP throughout the filtration process. They are looking to improve and develop new numerical modelling methods to better determine the cost benefit of PAC use.

Numerical Simulation of Simultaneous Electrostatic Precipitation and Trace Gas Adsorption: Electrohydrodynamic Effects (Clack 2017)

Figure 7. PM2.5 volume fraction in a 9-wire ESP channel segment under low (0.11 mA/m2, upper) and high (0.89 mA/m2, lower) EHD conditions.

Figure 8. Evolution of trace mercury (Hg) concentration in a 9-wire ESP channel segment under low (0.11 mA/m2, upper) and high (0.89 mA/m2, lower) current density.